Quality Control & Testing

The ability to test our work to NACE standards through each stage of processing, gives us advantages over less well structured competitors in the blast and coating industry. Diligent quality control and random testing is vitally important in the quest for efficient and accurate media usage, saving waste, time, money and the environment.

Our in house, full time, NACE Level 3 Coatings Inspector, Jamie Reynolds, is your first point of contact regarding all things quality control, testing and written reports. Jamie, can be contacted via reception on 01953 888 200.

Listed below are some of the testing terms and methods used to ensure our customers receive a first class service and end product.

Blotter Test

The Blotter Test is carried out on a daily basis, to establish clean, dry air passes through the air lines from the compressors.

Blast Media Inspection

A visual inspection to determine the abrasive media is not contaminated with salt, oil and blast process contaminants. This also monitors the abrasive integrity of the media after recycling.

Blast Profile Test

To establish that the blast profile/anchor pattern, is sufficient for good coating adhesion, as per specifications/Ripblast procedures.

Environmental Conditions Test

Check air temperature, steel temp, dew point and relative humidity, to ensure blasting and coating operations are carried out within client specifications / Industry and Ripblast standards.

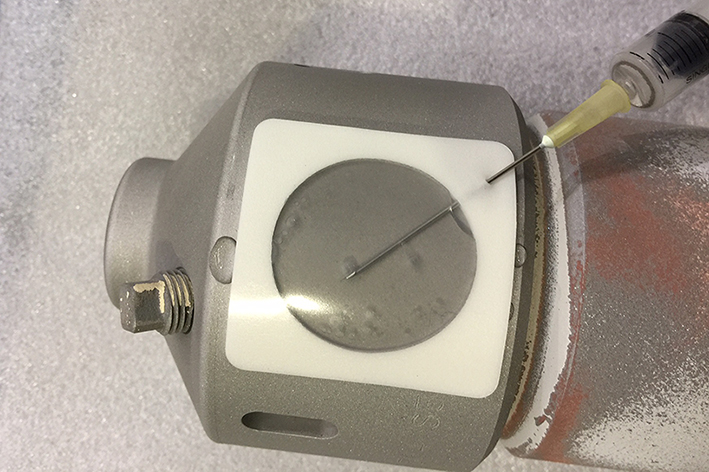

Soluble Salt Test, The Bresle Method

To determine the level of soluble salts on the substrate before coating is applied.

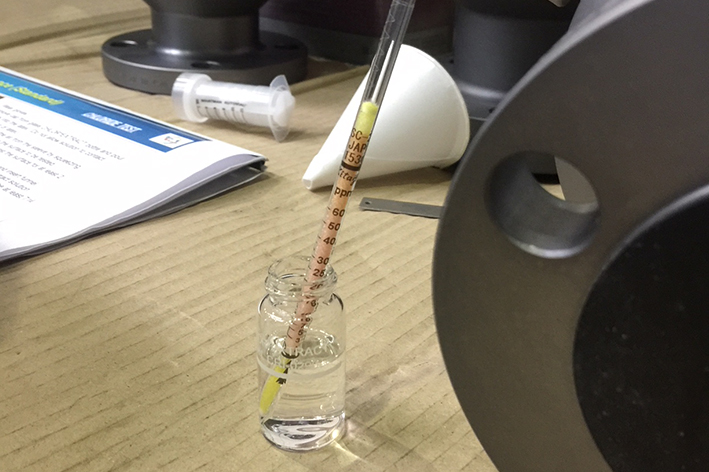

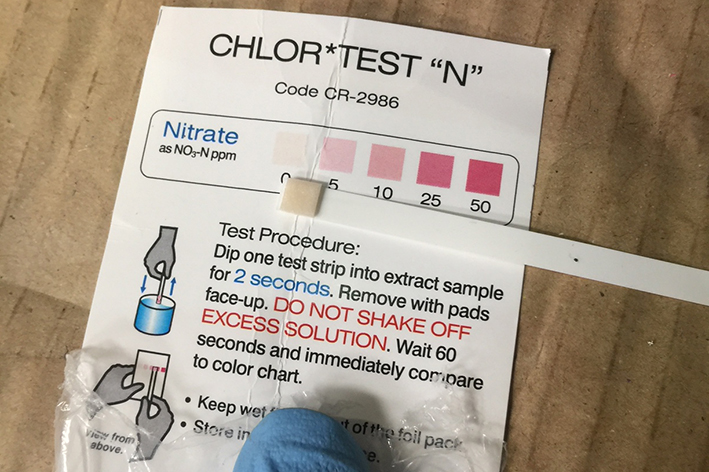

C.S.N

To determine the level of Chlorides, Sulphates and Nitrates on the substrate before blasting.

WFT: Wet Film Thickness

To determine the thickness of wet paint, to use as a guide to estimate what the film thickness will be when dry.

DFT: Dry Film Thickness

To determine the thickness of a dry coat of paint.

Low Voltage Holiday / Discontinuity Test

To establish that all the desired surface has been fully coated without causing damage to the coating.

Visual Check

Constant visual checks are carried out during the cleaning, blasting and coating processes, so any defects can be addressed and resolved.

Adhesion Test – Pull Off Test

The check the coating adhesion level to the substrate and test it is within specified parameters.

Adhesion Test – Bend Test

To establish how well a thermal sprayed coating, i.e. Zinc, Aluminium, Copper, Brass, Corten etc, has adhered to the substrate.

Batch Numbers

Batch numbers are recorded for each job to establish the traceability of all products used during processing.